Apologies for the lateness of this post – as life starts reopening I suddenly seem to be very busy!

The big news this month is that I’ve managed to get to a real exhibition – the first one for months.

When I first started learning about the shibori technique, I read about a Japanese textile company called Nuno, which created innovative fabrics that often had shibori characteristics. So when Japan House in London announced the exhibition Making Nuno: Japanese Textile Innovation from Sudo Reiko, I booked up straight away.

The exhibition is small but perfectly formed. A loom installation has the reels of thread set up to mimic one of the Nuno designs, and is beautifully lit to create striking shadows. Peering between the threads at the loom makes you feel as if you’ve just hit warp speed (ho ho).

The exhibition focuses on three of Nuno’s innovative fabrics. Polyvinyl alcohol is a synthetic resin that shrinks at 60°C. It is screenprinted onto polyester taffeta in a grid pattern and then heated to produce the wriggly “Jellyfish” fabric.

“Chemical lace” is made by stitching ribbon onto a water-soluble base, which is then dissolved to leave just the ribbon design.

The third fabric laminates washi paper onto velvet, producing a rich contrast in textures. Sorry there’s no image of this – it was white on white and was difficult to get a good photo.

A series of films shows the production process of many other fabrics in different mills around Japan and is worth watching. Upstairs, a patchwork “curtain” showcases samples of even more fabrics.

Making Nuno: Japanese Textile Innovation from Sudo Reiko runs at Japan House until 11 July.

Twining and coiling

On the making front, I managed to finish my twined dodecahedron!

I wasn’t sure whether to trim the ends further or leave them wild and woolly – Instagram opinion was fairly unanimous about leaving them wild. 🙂

In class at City Lit we made some twined ladles with paper string.

The string I used for the first one (on the left) was a bit bulky, so I made another one (on the right) that was much better.

I also had a go at starting twining with an overlapping base, which was a bit fiddly but worked OK in the end.

I also experimented with coiling, trying out a technique described in Annals of the South African Museum, a book owned by my tutor Polly Pollock. This technique, which incorporates ribs in the coiling, was used on bee skep in South Africa.

First of all I tried making a flat sample with rigid ribs (cane) and a bundle of dried unknown vegetation as the core, wrapped with very fine chair cane.

Then I tried it in the round using softer materials (polished flax for the ribs and core, and hemp for wrapping). This was much easier.

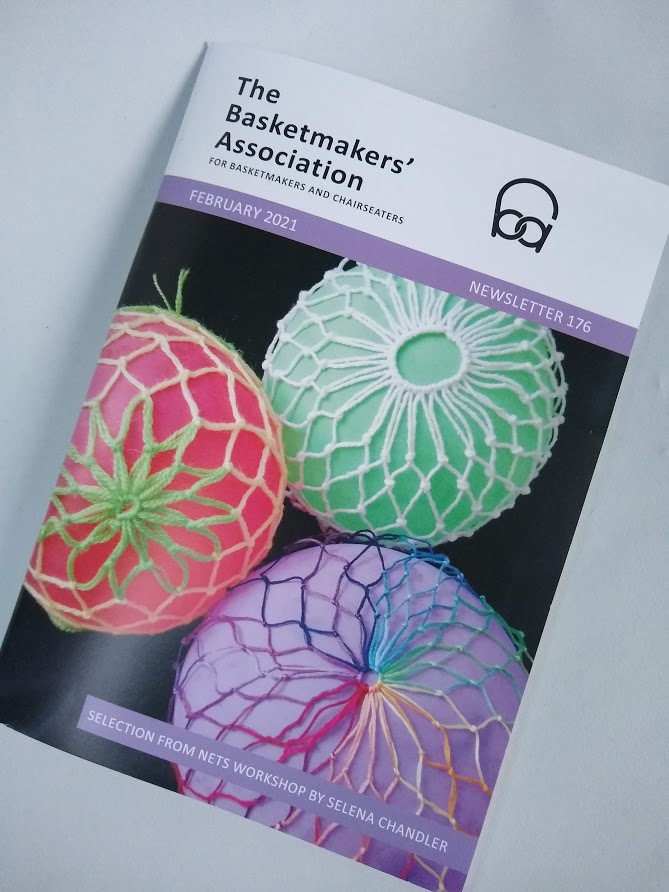

Finally, the first issue of the Basketmakers’ Association Newsletter that I edited was published this month. It was hard work for me and the volunteer designer Anita, but we’ve had extremely positive feedback, so it’s good to know that our efforts are appreciated!